Lux

LUX is EVLASER’s OEM solution for Marking, Engraving and Welding, a compact and versatile class IV LASER to be inserted in line or to be integrated with other automations. Easy to insert into automated line and island projects, LUX has high reliability and simple, complete and flexible interfacing.

All customer materials can be processed with LUX, thanks to the wide range of sources available:

- UV DPSS

- GREEN DPSS

- FIBER QSW

- FIBER CW

- MOPA

- CO2

- DIRECT DIODE 808nm, 980nm

Integrability

The compact size and robust design make LUX the best solution for the needs of system integrators and engineering firms.

CONNECTIVITY

LUX can be managed remotely via ETHERNET, Profinet or I / O signals that allow complete control of the marking and status of LASER.

FLEXIBILITY

The availability of 2 or 3-axis scanning laser heads and a wide range of objectives allows to find the optimal optical configuration for each customer’s processing.

Tech specs.

| Laser | Fibra Yb | DPSS Nd:Yag | DPSS Nd:Yag | CO2 |

| Technology | Qswitch / MOPA /CW / QCW | Qswitch | Qswitch | |

| Wavelenght | 1064nm | GREEN 532 | UV 355 | 10600 |

| Power | 20 to 10kW | 5 to 10W | 3 to 6W | 10 / 30 / 60 / 100W |

| Galvohead | 2D /3D (opt.) | 2D /3D (opt.) | 2D /3D (opt.) | 2D /3D (opt.) |

| Vision system | optional | optional | optional | optional |

| Rack Dimension ( LxPxH) | 510 x 450 x 285mm | 510 x 450 x 285mm | 510 x 450 x 285mm | 510 x 450 x 285mm |

| Head Dimension ( LxPxH) | 135 x 475 x 150mm | 135 x 475 x 150mm | 135 x 475 x 150mm | 135 x 475 x 150mm |

| Safety class | 4 according to EN 60825-1: 2014 | 4 according to EN 60825-1: 2014 | 4 according to EN 60825-1: 2014 | 4 according to EN 60825-1: 2014 |

How can we help you?

THE BEST LASER SOLUTIONS FOR YOUR REQUIREMENTS

Fill out the form to discover how our laser cleaning system can optimize your production and improve work quality.

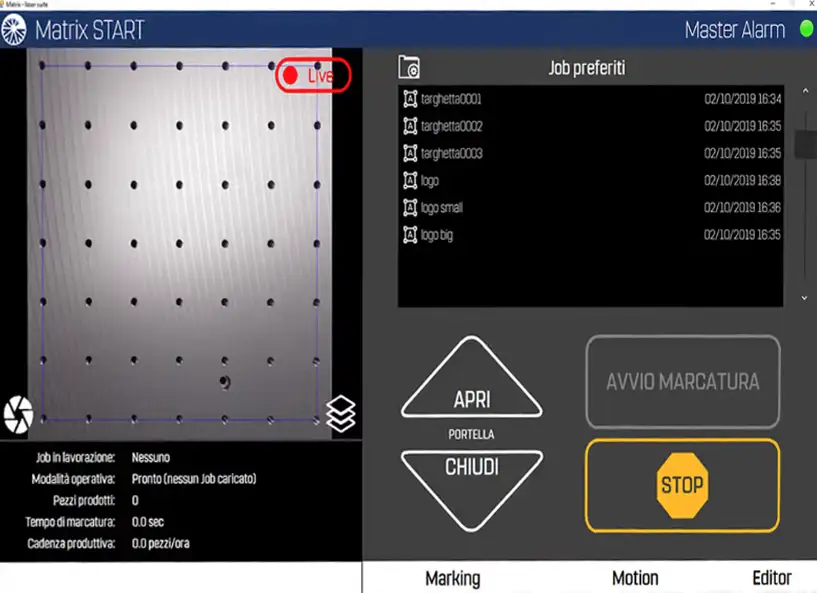

Matrix – Software Suite

Matrix is an advanced Software Suite developed thanks to thirty years of experience in Laser Marking, Engraving, Welding and Micromachining systems and ready for the challenges of Industry 4.0. It represents the state of the art of work functions and has the best man-machine interface on the market. This makes the training times of the operators practically nil and makes even more intense use pleasant. The practical EASYPAD touch on the front of the machine allows the operator to control the primary functions of MATRIX even without accessing the PC, allowing for a reduction in working times and making it easier to use.

ERP-MES

Integrated management of traceability thanks to the possible interfacing with management software, ERP, MES or database and to the reading and verification functions of texts or 1D / 2D codes through the integrated vision system

Add-on Packages

Modularity-oriented development allows the customer to configure MATRIX according to their needs. New needs will be easily addressed thanks to the packages and customizations that can be installed even after purchase using the convenient “LIVESERVICE” remote connection tool.

Smart Factory Ready

The Smart 4.0 package allows you to have remote control and monitoring of the system, with Reporting and Analytics on the productivity and quality of the work center and with the management of all the connections necessary for the factory interconnection.

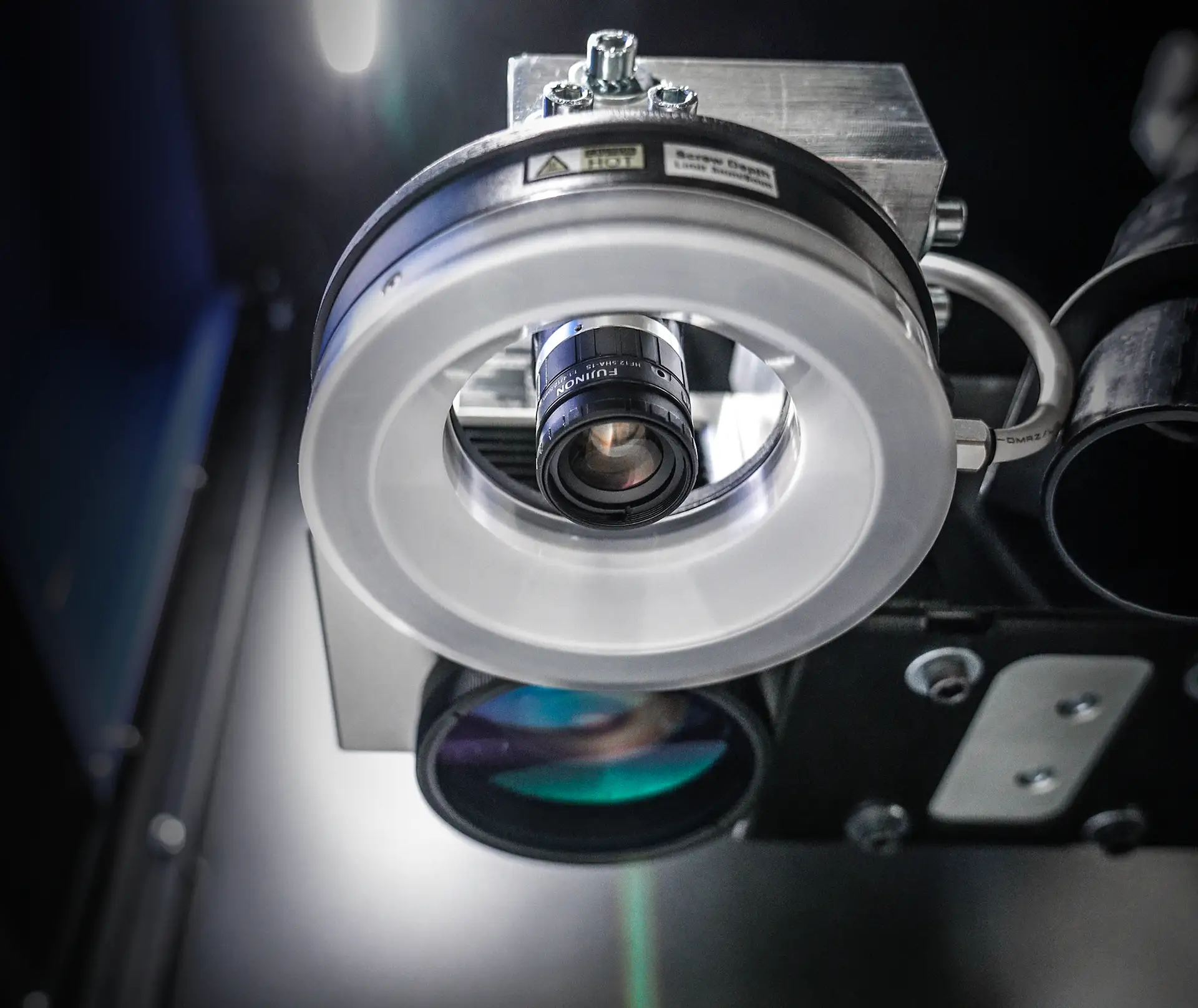

Vision Systems

Advanced Vision Devices (AVD), are a fundamental part of our offer, as they integrate into complex systems designed for the various application sectors. The use of recognition algorithms, neural networks and artificial intelligence makes the field of use and potential extremely extensive. The native integration of vision features with MATRIX software programming allows unparalleled flexibility in the management of production processes.

Pattern Matching

“PATTERN MATCHING” function for automatic recognition of the position of the piece and consequent automatic alignment of the machining.”PATTERN MATCHING” function for automatic recognition of the position of the piece and consequent automatic alignment of the machining.

Quality Inspection

“QUALITY INSPECTION” function for the recognition of attributes on the piece (color, shape, size, presence or absence of artefacts, surface finish, etc.), with the assignment of a Pass / Fail or a Class of Membership.

OCR – Barcode 1D/2D

Functionality of reading and verification of texts (OCR) or 1D / 2D codes (barcode, datamatrix, QR code, etc.) integrated with the software to fulfill the traceability needs of the process or to guarantee the quality and the result in the case of a marking.